OUR COMPANY

The company’s origin dates back to 2009 and is the result of a professional partnership with more than 150 years combined experience. In 2025, the company became part of EnSight Solutions, an OEM offering a wide range of food processing solutions.

At Simmtech, we design, develop, manufacture and install custom-built solutions, serving the Food & Beverages, Cosmetics and Biotechnology industries.

Licensed by PEO.

OUR SERVICES

Engineering Design

Process design is core knowledge at Simmtech, we manage the end-to-end design of all our projects including:

- Development of the Process and Instrumentation diagrams (P&IDs)

- FDA/CFIA Process Authority Filling and Validation

- Mechanical drawings (2D and 3D modelling)

- Process and Packaging Equipment Specification

- Process, Storage and Pressure vessels design

- Equipment Selection

- Utilities and Services Requirements

- Utilities and Services equipment sizing

Shop Assembly & Installation

We design, engineer and fully assemble “modular process skids” to suit clients' requirements, with the following benefits:

- Full control of the assembly process, assuring high quality fabrication and efficiency.

- Facilitate and expedite factory testing and factory acceptance test (FAT). Clients can see the equipment before it is shipped to site.

- Faster transportation, site installation and final commissioning of the new system

Electrical

Electrical

Electrical

We design, assemble and install all the electrical aspects of the project including:

- Control cabinets

- Motor control centres (MCC)

- Skids and field control and power wiring

- Plant networks.

- ESA certified installations

Automation

Electrical

Electrical

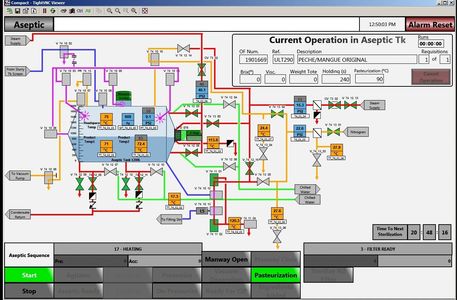

We design and provide the complete project automation platform, which includes:

- Operational Functional Analysis

- PLC programming

- HMI design

- Operational reporting systems

- Networks configuration and site support.

- Traceability solutions

- Database management and material stock control.

OUR BUSINESS

At Simmtech, we design, manage, manufacture, install and commission custom-built solutions, from complete Processing Lines to Turnkey Projects with highly advanced automation and management information systems.

We provide the following engineering and consulting services:

- Pre-development planning and Feasibility studies

- Process, electrical and automation designs

- Professional project management

- Shop assembly and Field installation

- Commissioning and Start up

- Preventative maintenance and Spare Parts

6750 Langstaff Road, Unit 3 Woodbridge Ontario L4H 5K2, ON, Canada - Telephone: 905-799-6111 - E-mail: info@simmtech.ca

Copyright © 2025 Simmtech Process Engineering Ltd. - All Rights Reserved.

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.